Four Barriers For Four Wetting Potentials: How To Design Effective Exterior Walls

What are the four barriers of the four wetting potentials when designing effective exterior walls? They are Air, Water, Heat and Vapor barriers. This is a four-part blog article, the first of which discusses air barrier systems.

What are the four wetting potentials?

The four wetting potentials affecting an exterior wall are

- Moisture Transport Due To Air Flow (Air Barrier),

- Liquid Water Ingress (Water Barrier),

- Dew Point ( Heat Barrier Location),

- Vapor Migration ( Vapor Barrier).

How Do We Properly Deal With These Four Wetting Potentials?

Good HAMM. What the #@$& is HAMM? HAMM is the 4 barriers needed to protect a building against the effects of weather. These barriers are [H] Heat Barrier, [A] Air Barrier, [M]L Water Barrier ( Liquid Moisture ), [M]V Vapor Barrier ( Gaseous Moisture ). Together, HAMM is the Weather Barrier System.

Good HAMM effectively deals with thermal transfer, wetting and drying potentials:

Heat Barrier: Thermal loss, thermal gain, and bridging. Wetting potential due to a dew point (location)

Air Barrier: Thermal loss and gain. Wetting potential due to moisture transport via air flow.

Water Barrier: Wetting potential due to liquid moisture intrusion into and through the Building Enclosure System.

Vapor Barrier: Wetting potential due to vapor diffusion into and through the Building Enclosure System.

What is an Air Barrier System?

Air Barrier System ( ABS ): A system of building components within the building enclosure system ( BES ) designed and installed in such a manner as to stop the flow of air into and out of buildings through the building enclosure system. Air barrier systems can be classified as either Vapor Permeable Air Barrier Systems or Air And Vapor Barrier Systems. Air flow into and out of buildings is caused by wind pressure, fan pressure, and stack pressure.

Why stop the flow of air into and through the building enclosure system?

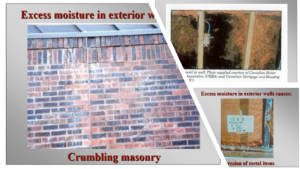

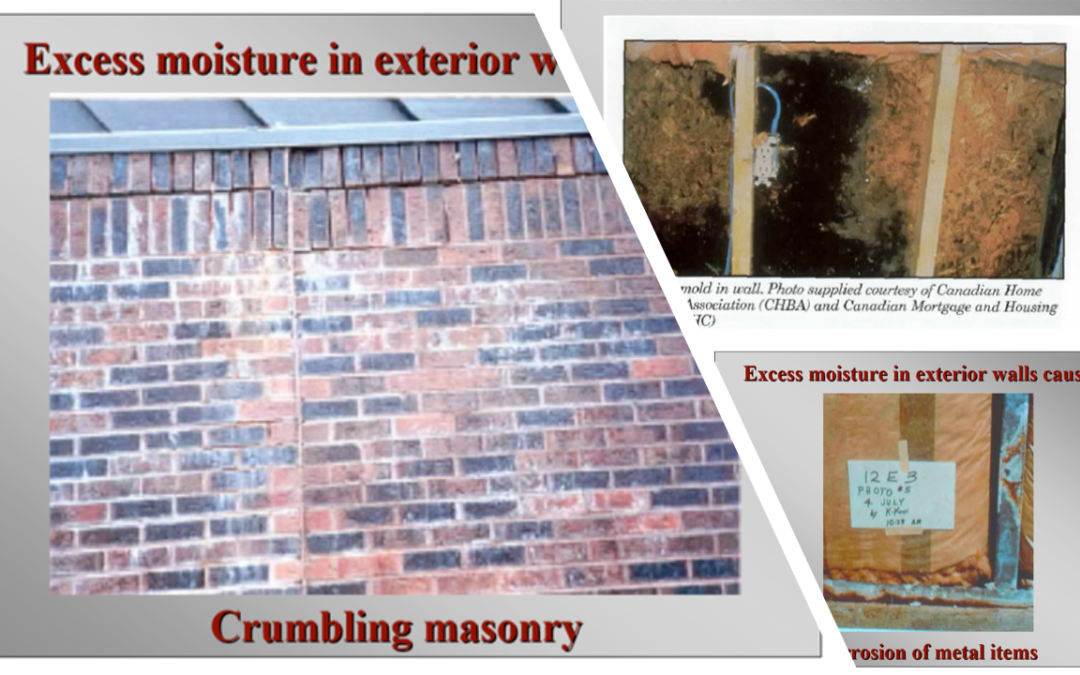

First and foremost, air flow has the ability to transport exponentially more moisture into and through the building enclosure system than occurs through vapor migration or diffusion. Estimates range from 30 to 200 times more moisture transport occurs via air flow than vapor migration. Excess moisture in exterior walls causes (see image left) crumbling masonry, Mold, and corrosion of metal items as well as Efflorescence (not shown).

Next, air flow into and out of buildings can affect the location of the dew point. Air leakage into and out of buildings causes the HVAC system to expend extraneous energy in order to maintain the building’s desired temperature and humidity levels. Air flow is a vehicle by which sound travels. Air flow is a vehicle by which particulate matter travels. Finally, Air flow is a vehicle by which odors and gaseous substances travel.

Why use Air Barrier Systems?

The use of Air Barrier Systems has many benefits by reducing building Enclosure System problems, improves indoor air quality, reduces building energy consumption, reduces fossil fuel consumption, reduces pollution emissions, reduces Greenhouse Effect, and reduces building heating and cooling costs.

For the life of your building, download the Air Barrier Systems Construction Specifier.

For the life of your building, download the Air Barrier Systems Construction Specifier.

Recently, Len spoke at the Architect Builders Convention ABX & Greenbuild 2017 (November 2017) on “The Four Barriers For Effective Exterior Wall Design”. They took a look at

- The four wetting potentials that above grade exterior walls are subjected to.

- The four barriers needed for effective exterior wall performance

- The science and physics of how the four barriers work to create effective exterior walls

- Hygrothermal modeling tools to assess exterior wall performance

Len Anastasi has been working in the construction industry for over 30 years in masonry, waterproofing and restoration work.

He currently owns EXO-TEC Manufacturing, Inc., EXO-TEC Solutions, Inc. and EXO-TEC Consulting, Inc.

In his construction and consulting work, he has performed inspections and repairs on over 300 buildings.

Len has given expert testimony in trials and reviews on dozens of legal cases.

He is a member of ASTM’s E 06 Committee, the Boston Society of Architects Building Enclosure Council, Air Barrier Association of America, the Construction Specifications Institute, and the International Concrete Repair Institute.

Book Len for your Next Event!

Len Anastasi has been working in the construction industry for over 30 years in masonry, waterproofing and restoration work.

He currently owns EXO-TEC Manufacturing, Inc., EXO-TEC Solutions, Inc. and EXO-TEC Consulting, Inc.

In his construction and consulting work, he has performed inspections and repairs on over 300 buildings.

Len has given expert testimony in trials and reviews on dozens of legal cases.

He is a member of ASTM’s E 06 Committee, the Boston Society of Architects Building Enclosure Council, Air Barrier Association of America, the Construction Specifications Institute, and the International Concrete Repair Institute.

Book Len for your Next Event!

Please contact me about the possibility of setting up a lunch and learn workshop for my office.

Hi Matt,

Where is your office located?

Len

Depending upon its measurable level of resistance to airflow, the air retarder can, in certain instances, be incorporated into the overall air barrier for an exterior wall system or assembly. However, these products alone typically cannot prevent airflow across a wall assembly and, as such, should not be used in lieu of an effective air barrier.