Four Barriers For Four Wetting Potentials: How To Design Effective Exterior Walls

What are the four barriers of the four wetting potentials when designing effective exterior walls? They are Air, Water, Heat and Vapor barriers. This is the third part in our four-part series. How To Design Effective Exterior Walls Part 3 – Heat Barrier.

While Part 1 Air Barrier systems | Part 2: Water Barrier systems | Part 3: Heat Barrier Systems | Part 4: Vapor Barrier Systems

There are the four wetting potentials affecting exterior walls; Moisture Transport Due To Air Flow (Air Barrier), Liquid Water Ingress (Water Barrier), Dew Point ( Heat Barrier Location), Vapor Migration ( Vapor Barrier).

How Do We Properly Deal With These Four Wetting Potentials?

Good HAMM. HAMM is the 4 barriers needed to protect a building against the effects of weather. These barriers are [H] Heat Barrier, [A] Air Barrier, [M]L Water Barrier ( Liquid Moisture ), [M]V Vapor Barrier ( Gaseous Moisture ). Together, HAMM is the Weather Barrier System.

Good HAMM effectively deals with thermal transfer, wetting and drying potentials:

Heat Barrier: Thermal loss, thermal gain, and bridging. Wetting potential due to a dew point (location)

Air Barrier: Thermal loss and gain. Wetting potential due to moisture transport via air flow.

Water Barrier: Wetting potential due to liquid moisture intrusion into and through the Building Enclosure System.

Vapor Barrier: Wetting potential due to vapor diffusion into and through the Building Enclosure System.

What is a Heat Barrier System?

The Heat Barrier System resists the thermal transfer through the building enclosure system. We know the R-Value is the measure of resistance to thermal transfer. The higher the R-Value, the greater the resistance. The greater the resistance, the lower the heat gain or heat loss, thereby, decreasing the energy demands of heating and cooling systems.

Thermal Performance

Factors affecting thermal performance of insulation are air leakage through gaps in the insulation, wind wash effect of fibrous insulation, and thermal bridging.

The location of the heat barrier, in a properly designed and constructed building enclosure system, determines the location of the dew point.

Why use Heat Barrier Systems?

The use of Heat Barrier Systems reduces heat transfer through the building enclosure.

Bottom line, big picture…… heat seeks cold. Heat barriers prevent heat from seeking cold.

EXO-TEC Heat Barrier Solutions

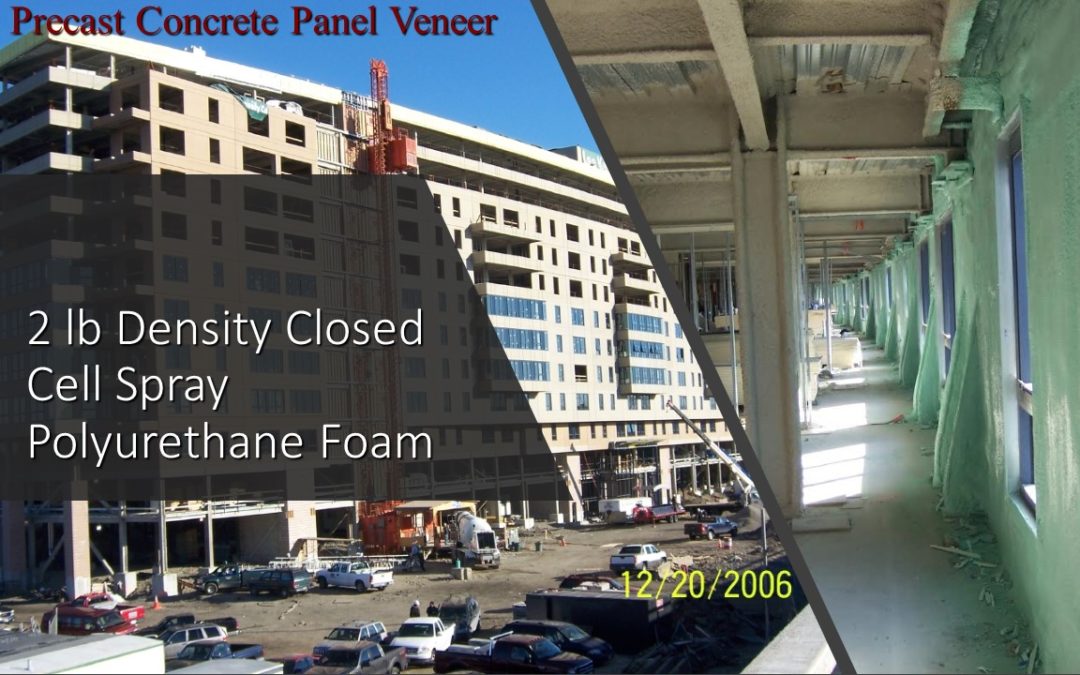

BASF 2-pound Density Closed Cell Spray Polyurethane Foam [image shown above] is our solution to provide a heat barrier solution on the back side of the precast concrete panel veneer building construction. Below is the Neponset Landing building in Quincy, MA using our solution.

Beware of the Dew Point Analysis. It does not work. Read on.

The Dew Point Analysis Tool

The Dew Point Analysis Tool is the most widely used design tool in determining the suitability of building enclosure system design for moisture control. “But,” says Len, “Guess what!? It doesn’t work.”

Oak Ridge National Laboratories [ http://www.ornl.gov/sci/btc/apps/moisture/ibpe_sof1.html]

“ Out of Date: Dew-Point(Glaser)”

“The Dew-Point method as detailed in ASHRAE has been a common method to assess the moisture balance of a building component by considering vapor diffusion transport in its interior. However, this method does not allow for the capillary moisture transport in the component, nor for its sorption capacity, both of which reduce the risk of damage in case of condensation. Furthermore, since the method only considers steady-state transport under heavily simplified boundary conditions, it cannot reproduce individual short-term events or allow for rain and solar radiation. It is meant to provide a general assessment of the hygrothermal suitability of a component, not to produce a simulation of realistic heat and moisture conditions in a component exposed to the weather prevailing at its individual location.”

Exo-tec has several waterproofing products from below-grade to rooftop, wall drainage solutions for above- and below-grade waterproofing solutions intended for both pre-concrete and post-concrete pour applications. Our fluid-applied waterproofing and dampproofing products stand up to the toughest weather and job site conditions. We have air barrier solutions, high tolerance floor solutions, masonry anchors, and soy-based cleaners and strippers.

Signup for our email newsletter to stay informed of the events Len speaks.

Book Len for your Next Event!

Next month Part 4 of this series we discuss the Vapor Barrier.

Len Anastasi has been working in the construction industry for over 30 years in masonry, waterproofing and restoration work.

He currently owns EXO-TEC Manufacturing, Inc., EXO-TEC Solutions, Inc. and EXO-TEC Consulting, Inc.

In his construction and consulting work, he has performed inspections and repairs on over 300 buildings.

Len has given expert testimony in trials and reviews on dozens of legal cases.

He is a member of ASTM’s E 06 Committee, the Boston Society of Architects Building Enclosure Council, Air Barrier Association of America, the Construction Specifications Institute, and the International Concrete Repair Institute.

Book Len for your Next Event!

Len Anastasi has been working in the construction industry for over 30 years in masonry, waterproofing and restoration work.

He currently owns EXO-TEC Manufacturing, Inc., EXO-TEC Solutions, Inc. and EXO-TEC Consulting, Inc.

In his construction and consulting work, he has performed inspections and repairs on over 300 buildings.

Len has given expert testimony in trials and reviews on dozens of legal cases.

He is a member of ASTM’s E 06 Committee, the Boston Society of Architects Building Enclosure Council, Air Barrier Association of America, the Construction Specifications Institute, and the International Concrete Repair Institute.

Book Len for your Next Event!